How long can a 300hp outboard really run at peak performance? The answer isn’t just in the engine’s specs. Maintenance also matters. This guide offers helpful tips for both fuel and electric 300HP outboards. It will help you get the best performance and longer life from your engine.

How long can a 300HP outboard motor run continuously?

300HP fuel outboards

A well-maintained 300HP fuel outboard engine can typically run continuously for 6 to 8 hours under optimal conditions. The actual runtime can change based on several factors. These include engine load, throttle use, fuel quality, and cooling system efficiency. Regular servicing is essential for maintaining this performance and includes tasks such as oil changes, inspecting the fuel system, and maintaining the cooling system. This helps to prevent overheating and mechanical issues during operation.

For instance, at a cruising speed of 3,500 to 4,500 RPM and under normal load and cooling conditions,Yamaha F300 V6 4.2L can run continuously for 8 to 10 hours. It usually runs at speeds of 5,000 to 6,000 RPM. It has a compression ratio of 10.3:1 and can produce a maximum alternator output of 70 amps. When running at full speed (about 6,000 RPM), it is safe to run for 1 to 1.5 hours. After that, it is best to let the engine rest or idle for a short time.

Maintaining consistent oil pressure, temperature stability, and high fuel quality is critical for achieving this level of endurance. Yamaha recommends changing the engine oil every 100 hours of use or annually, whichever occurs first. Additionally, letting the engine idle for 10 to 15 minutes after long runs can help reduce wear and stabilise oil circulation.

300HP electric boat motors

High-power electric outboards like the ExploMar 300HP offer impressive torque and instant acceleration with near-silent operation. Continuous runtime depends primarily on battery capacity and cruising speed. With ExploMar’s modular lithium-ion battery systems, the 300HP model can typically run 3 to 6 hours continuously at moderate cruising speeds (around 60–70% power output) before requiring a recharge. In real-world tests similar to those featured on Plugboats, a 300HP-class electric outboard running on a 200 kWh battery bank can deliver over 5 hours of operation at cruising speed or 1–1.5 hours at full power.

While the total runtime of an electric 300HP outboard is shorter than that of a petrol counterpart, electric propulsion systems require less routine maintenance, have fewer moving parts, and deliver high efficiency across variable speeds—making them increasingly viable for both commercial and recreational vessels.

Runtime Comparison: 300HP Fuel vs Electric Outboards

| Model | Power Type | Continuous Runtime (Cruising) | Full Throttle Runtime | Key Notes |

|---|---|---|---|---|

| Yamaha F300 V6 4.2L | Petrol (4-Stroke) | 8–10 hours | 1–1.5 hours | Ensure regular oil changes and cooling checks; avoid overheating. |

| ExploMar 300HP Electric Outboard | Electric (Lithium Battery System) | 3–6 hours | 1–1.5 hours | Runtime varies by battery size (e.g., 200 kWh pack gives ~5 hrs at cruise). |

Key Factors Affecting Runtime

Boat load, water conditions, and throttle habits

Excessive vessel load, rough water, and erratic throttle usage place significant strain on a 300 horsepower outboard. Avoiding abrupt acceleration and maintaining moderate cruising speeds can substantially improve fuel or battery efficiency. Consistent monitoring of boat load and weight distribution further enhances runtime and prolongs engine life.

Yamaha’s official performance bulletin shows some interesting data. A Sportsman Open 232 with a single F300XSB2 engine, which has 300 hp, reached a speed of about 46 mph. This speed was measured at wide-open throttle, around 5,500 rpm. It burned about 25 gallons per hour. In contrast, cruising at 2,500–3,500 rpm used much less fuel. This shows that heavy throttle reduces runtime with the same test load, which includes 50 gallons of fuel, two batteries, crew, and safety gear.

Fuel or battery type and efficiency

Fuel-powered engines benefit from using the manufacturer-recommended octane and proper maintenance, while electric outboards perform best with high-capacity lithium-ion batteries. Charging patterns, temperature control, and cycle management are critical for electric motor longevity. The table below demonstrates typical runtime differences based on fuel or battery selection.

Propeller size and condition

Correct propeller selection directly impacts efficiency and runtime. Damaged, bent, or corroded propellers increase strain on engines, reducing fuel economy and battery endurance. Proper propeller maintenance ensures optimal thrust, enhances performance, and prevents unnecessary wear on both fuel and electric outboards.

Maintenance Tips for 300HP Fuel Outboards

1. Regular engine inspection and cleaning

Inspecting your 300hp outboard motor regularly is crucial.

Check the engine compression to ensure efficient combustion:

- Remove the spark plugs, making sure to note the location of each lead.

- Push the compression gauge into the spark plug socket (for gauges with a rubber end) or screw in the type that has a thread.

- Remove the kill switch lanyard or push the kill switch to protect the electronic block by short-circuiting the ignition system.

Verify the kill switch and stop button functionality to guarantee safety during operation.

- Disconnect the kill switch: two wires, the first connected to ground, the second to the electronic box.

- Adjust your multimeter to an ohmmeter.

- Connect the clip and cord to the kill switch.

- Connect the multimeter to each wire.

- The current shouldn’t flow; the resistance is infinite.

- Briefly push the stop button.

- The current should flow; the ohmmeter should show a weak reading.

- Remove the cord.

- The current should flow; the ohmmeter should show a weak reading

Clean the engine exterior to remove salt deposits, grime, and other contaminants that may accelerate wear or corrosion.

2. Oil changes, fuel system checks, and spark plug maintenance

Routine oil and filter replacement every 100 hours or annually is vital for engine longevity.

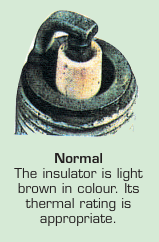

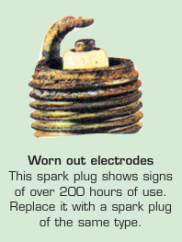

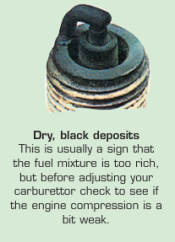

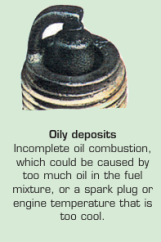

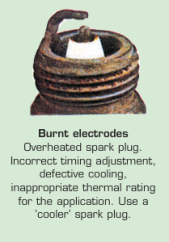

Inspect spark plugs for fouling or wear, and replace or adjust them as necessary.

Check and clean the fuel filter and carburettor to prevent blockages.

Adjust the idling rate, fuel/air mix, and bowl fuel level to optimise engine performance.

Ensure the gearbox oil is replaced on schedule and that the fuel mix is prepared accurately for two-stroke engines.

3. Cooling system flushing and anti-corrosion treatment

Flush the cooling system with fresh water after saltwater use to prevent scale and salt deposits.

Dismantle, check, and refit the thermostat to ensure proper temperature regulation.

Inspect the water pump impeller and replace it if worn.

Apply anti-corrosion treatments to critical metal components to prevent rust and extend engine life.

4. Lubrication of moving parts and lower unit maintenance

Lubricate all moving parts including gimbals, steering linkages, and throttle components.

Remove the lower leg for inspection, and check the propeller for damage or wear.

Replace or repair as needed to maintain efficiency.

Additionally, check the oil pressure regularly to detect early signs of mechanical issues.

Maintenance Tips for 300HP Electric Outboards

1. Battery care: charging cycles, storage, and temperature management

Proper battery maintenance is the cornerstone of electric outboard performance. Follow balanced charge and discharge cycles, store batteries in controlled temperature environments, and avoid deep discharges. Use battery management systems (BMS) to monitor voltage, capacity, and cell balance, ensuring prolonged lifespan.

2. Motor inspection: brushless components, seals, and waterproofing

Regularly inspect the brushless motor components for wear. Check seals for leaks and verify waterproofing integrity. Early detection of damage prevents costly repairs and ensures consistent power delivery.

3. Cooling and thermal management in high-power electric outboards

High-performance electric motors generate significant heat. Use active cooling systems, monitor temperature sensors, and avoid prolonged high-load operation to prevent thermal shutdowns. Maintaining proper thermal management is crucial for both runtime and battery longevity.

4. Software or ECU updates for optimal performance

Manufacturers frequently release firmware updates for motor control units. Updating your outboard’s software ensures optimal efficiency, runtime, and compatibility with new features. Neglecting updates may reduce performance and potentially shorten the lifespan of critical electronic components.

Propeller Optimisation for Better Runtime

Choosing the right propeller for speed vs efficiency

Select a propeller that balances speed and efficiency. High-pitch propellers allow faster top speeds but can reduce fuel and battery efficiency, while low-pitch propellers improve endurance and runtime. Consider vessel weight, cruising speed, and operating conditions when choosing the optimal propeller.

Repair or replacement of damaged propellers

Inspect propellers regularly for nicks, bends, or corrosion. Minor damage can be repaired, but severely damaged propellers should be replaced immediately. This preserves engine efficiency and prevents further mechanical strain.

| Propeller Type | Recommended Use | Impact on Runtime |

|---|---|---|

| High-pitch | Speed-focused boating | Reduced fuel/electric efficiency |

| Low-pitch | Endurance and efficiency | Extended runtime |

| Damaged/Corroded | Repair or replace | Restores efficiency and prevents engine strain |

When to Seek Professional Maintenance

Annual servicing recommendations for both fuel and electric outboards

Even with diligent personal maintenance, annual professional servicing is recommended. Technicians perform in-depth inspections, recalibrations, and preventive maintenance that may be difficult to achieve at home. This ensures your 300 horsepower outboard operates reliably year-round.

Warning signs your 300HP outboard needs expert attention

Watch for unusual vibrations, overheating, loss of power, erratic battery behaviour, or abnormal engine noises. Immediate professional inspection can prevent minor issues from escalating into costly repairs.

Conclusion

Maximising runtime for your 300 hp electric boat motor involves a combination of diligent maintenance, smart operational habits, and attention to both fuel and electric systems. Regular engine inspections, timely oil and battery care, propeller optimisation, and recognising early warning signs all contribute to reliable, long-lasting performance. By applying these strategies, you can enjoy safe, efficient, and enjoyable boating experiences.

Frequently Asked Questions

1. How often should I replace the battery in a 300HP electric outboard?

Typically, lithium-ion batteries require replacement after 1,200–2,500 charge cycles. Monitoring voltage, temperature, and capacity will help determine the optimal replacement time.

2. Can I use a high-pitch propeller for extended cruising?

High-pitch propellers improve speed but reduce fuel or battery efficiency. For long-distance cruising, low or medium-pitch propellers are recommended to extend runtime.

3. What are the signs of fuel system issues in a 300HP outboard?

Indicators include rough idling, slow acceleration, black smoke from the exhaust, or unusual engine noises. Immediate inspection and maintenance prevent engine damage.

4. How do temperature extremes affect electric outboard runtime?

High temperatures accelerate battery degradation, while extreme cold reduces charge efficiency. Keeping batteries within recommended temperature ranges maximises performance and longevity.

5. Should I service my outboard before seasonal storage?

Yes. Perform cleaning, fuel stabilisation, oil changes, and battery maintenance prior to storage. This prevents corrosion, fuel deterioration, and capacity loss.