Best EVA Foam Boat Flooring in 2026: SeaDek vs DEKit vs Alternatives

If you want your deck to feel better underfoot, stay grippy when it’s wet, and clean up fast after a long day on the water, EVA foam boat flooring is usually the category you take into consideration. It helps protect the vessel’s structure and keep its occupants safe. But with so many products in the market, how can you choose the best EVA foam boat flooring?

This guide helps you choose the best Eva boat flooring for your boat and your habits, using real spec details and the practical stuff boat owners actually deal with.

What Makes the Best EVA Foam Boat Flooring?

When you’re shopping for the best boat foam flooring, you’re not just picking a color and pattern. You’re choosing a material system: foam density and cell structure, texture geometry, adhesive type, and how that all behaves after months of spray, sun, and cleaning.

| What to check | What “good” looks like | Why it matters on a boat | Quick way to verify |

|---|---|---|---|

| Foam type | Closed-cell marine-grade EVA / PE-EVA | Resists water uptake, stays lighter, reduces mildew smell risk | Product page calls out closed-cell or marine-grade EVA |

| Thickness options | Multiple thicknesses for comfort vs. edge profile | Thicker feels nicer, thinner conforms easier and edges snag less | Look for listed thickness ranges |

| Adhesive backing | Quality PSA (often referenced as 3M PSA by brands) | Edges lifting is the #1 DIY failure mode | Brand documentation names the PSA system and prep steps |

| Texture design | Purposeful non-skid texture (brushed, diamond, faux teak grooves) | Grip + comfort without turning into a dirt trap | Zoom in: texture has depth, not just printed lines |

Sources include SeaDek product information and sheet listings, DEKit material descriptions (including 3M PSA references), and typical EVA foam closed-cell explanations from marine flooring publishers.

Marine-Grade Closed-Cell Foam & Water Resistance

The backbone of the best Eva foam boat flooring is closed-cell structure. Closed-cell EVA has sealed microscopic pockets that make it far more resistant to soaking up water than open-cell foam or carpet. In real life, that means it doesn’t get heavy after a wet day, it dries faster, and it’s less likely to become a “hidden moisture” problem under gear and mats.

One nuance: “water-resistant” doesn’t mean “nothing can ever get under it.” If you trap water under the foam (especially at edges) and the adhesive bond is compromised, you can still get funky odors. That’s why surface prep and edge sealing matter just as much as picking the best Eva foam for boats.

Traction and Safety in Wet Conditions

Traction is about predictable grip when the deck is wet, when there’s sunscreen on it, when you’re stepping aboard with sandy feet, and when you’re moving fast around a hatch. Texture patterns like brushed, diamond, and faux-teak grooves create micro “channels” that help water move away from the contact point, improving confidence underfoot.

If you fish a lot, prioritize textures that don’t become a scale-and-slime sponge. Some deep patterns feel great but hold more debris. If you cruise barefoot, brushed textures often help keep the floor comfortable, cleanable, and still non-skid.

Durability Against UV, Salt, and Wear

UV is the long game. Even if your boat lives under a cover, the swim platform and cockpit edges still get blasted. Premium systems commonly talk about UV protectants and long-term appearance. For example, DEKit specifically describes combining its cross-linked PE/EVA foam with UV protectants and a named PSA approach, and it frames the result as a multi-year solution.

Salt and abrasion are the short game. Every time you drag a cooler, drop a sinker, or grind sand into the surface, you’re testing tear resistance and surface integrity. When you’re hunting for the best Eva boat flooring, pay attention to whether the brand publishes hardness, density, or “not easy to tear” claims with specifics.

Customization and Aesthetic Options

This is where the top-tier options really pull away. A custom-cut kit isn’t just about looking sharp. It usually means fewer seams, cleaner cutouts around hatches and hardware, and less exposed edge overall, which is exactly where lifting and grime buildup tend to start.

If resale value matters to you, or you want the deck to look like it came from the factory, custom-fit is often money well spent. If you’re working with a tighter budget, sheet material can still be the best Eva foam boat flooring for your needs, as long as you approach installation like a proper build: accurate templates, careful alignment, and real pressure on every edge.

Best EVA Foam Boat Flooring Brands

SeaDek EVA Foam Boat Flooring

SeaDek is the name people reference when they’re describing the best Eva foam boat flooring. It’s widely positioned as custom marine flooring and also sells DIY-friendly sheet material. SeaDek’s messaging emphasizes peel-and-stick installation and extensive customization across colors, patterns, and textures.

If you’re evaluating the best Eva foam boat flooring on measurable details, start with what is published: sheet dimensions, thickness, and texture type. One brushed sheet listing specifies 40″ x 80″ at 5mm thickness and describes the surface as having non-skid qualities. That combination is a practical middle ground for DIY: 5mm is typically enough to add comfort, while still keeping edges low-profile so you’re less likely to catch an edge near hatches or step transitions.

The sheet size matters too. A larger panel can reduce seam count on simple layouts, which is not only an aesthetic win. Fewer seams usually means fewer edge lines where grime collects and fewer opportunities for a corner to start lifting if pressure or surface prep wasn’t perfect.

Who it’s best for: you want a premium look, reliable feel underfoot, and you don’t want to gamble on off-brand adhesive performance.

Watch-outs: premium materials deserve premium prep. If you install on a contaminated surface, you can still get edge lift. The product won’t save you from skipped cleaning steps.

DEKit EVA Foam Boat Flooring

DEKit leans hard into customization and thickness variety. On its designs and colors page, DEKit lists multiple thickness categories: standard 3mm and 5mm, and two-color options at 6mm, 13mm, and 25mm. That’s a meaningful spread if you want a softer deck feel (thicker) or you’re trying to keep the finished edge profile low (thinner).

DEKit also explicitly ties its material system to cross-linked PE/EVA foam, 3M PSA, and UV protectants, and it highlights an industry-leading 3-year warranty on the material (with important caveats around adhesive and installation conditions).

Who it’s best for: you want a custom look, you care about thick comfort options, and you like the idea of a documented warranty position.

Watch-outs: read the warranty language carefully. Like many PSA-backed systems, the adhesive bond is heavily dependent on prep, surface condition, and install environment.

Marine Mat EVA Foam Boat Flooring

MarineMat is often chosen by boat owners who care more about underfoot comfort and long days aboard than aggressive textures or high-contrast patterns. Compared with some harder-feel EVA options, MarineMat is known for a noticeably softer, more cushioned ride, which makes a difference if you spend hours standing at the helm or moving around the cockpit.

MarineMat uses marine-grade closed-cell EVA foam designed to resist water absorption, staining, and UV exposure. Like other premium players in the best EVA foam boat flooring category, it focuses heavily on custom-cut solutions rather than generic sheets. That means fewer seams, cleaner transitions around hatches and hardware, and less edge exposure over time.

From a traction standpoint, MarineMat textures are generally more refined than aggressive. They prioritize barefoot comfort and predictable grip rather than sharp non-skid. For cruising boats, pontoons, and family-focused layouts, this balance works extremely well. On hardcore fishing decks where slime and scales are constant, some owners may still prefer deeper textures.

Who it’s best for: owners who want a premium, soft-feel deck with a clean, custom look and spend long hours on board.

Watch-outs: MarineMat typically sits in the premium pricing tier and is less DIY-oriented. If you want sheet material for quick installs or small projects, other brands may offer more flexibility.

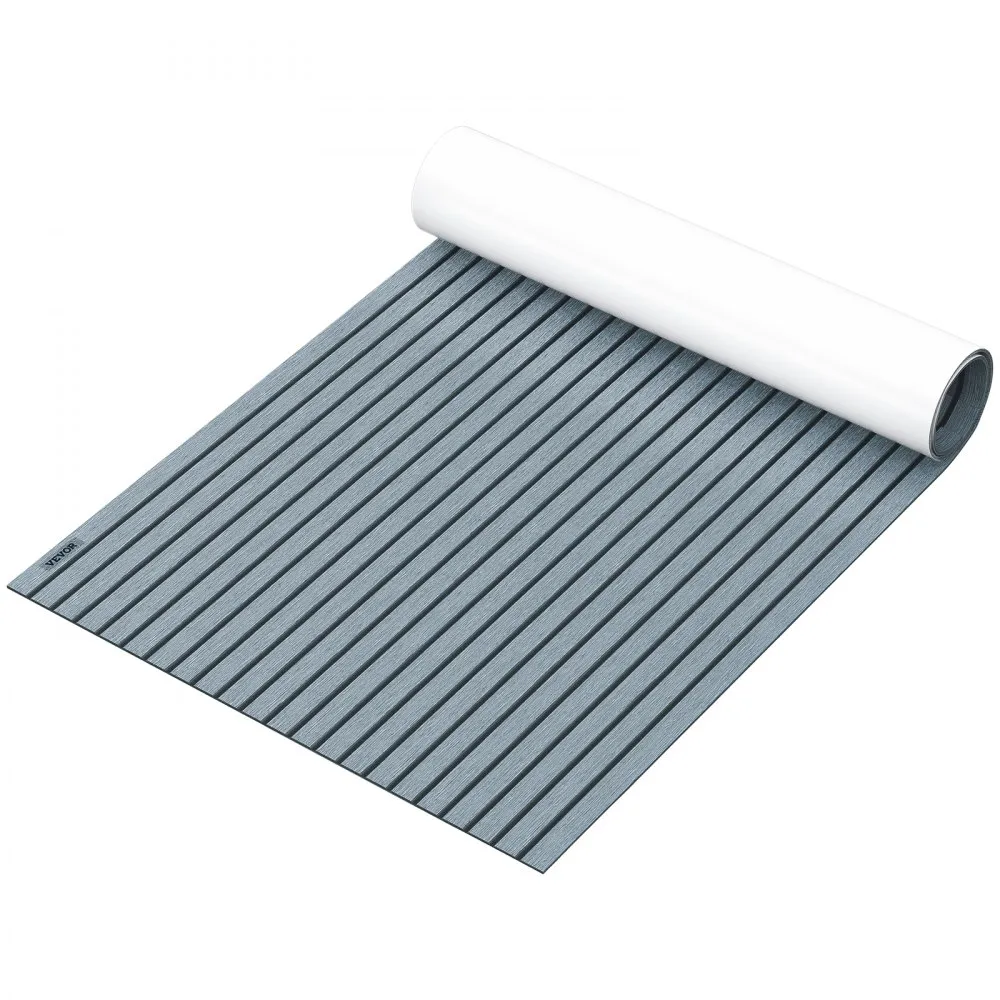

VEVOR Boat Flooring EVA Foam Decking

VEVOR is easy to assess when you treat it like a spec-based DIY material rather than a premium kit. The upside is that listings often publish hard numbers. One faux-teak EVA sheet is listed at 94.5 x 47.2 inches, about 0.2″ thick (roughly 6mm), with a stated hardness value of 60. Those numbers help you compare feel and thickness on paper.

Just keep the interpretation honest: thickness and hardness don’t automatically translate into long-term edge stability. With budget sheets, the “real product” is your installation—templating accuracy, clean substrate, rolling pressure, and edge attention will decide whether it stays down and looks clean after a season of heat cycles.

Who it’s best for: you want the best boat foam flooring value for a DIY install on a smaller deck area, swim platform, cooler top, or a “test run” before investing in a full custom kit.

Watch-outs: value sheets can look fantastic, but your outcome is strongly tied to surface prep, accurate cutting, and rolling pressure. Also, match your expectations: if you want a “factory fit” look around complex curves, you’ll fight seams.

KT GuoMei Boat Flooring EVA Foam

KT GuoMei positions itself as a dedicated EVA boat flooring manufacturer and highlights custom sizing, patterns, and DIY-friendly formats. If your priority is getting a specific sheet size or pattern and you’re comfortable doing your own cutting, brands like this can be a practical alternative.

KT GuoMei listings show common large-sheet sizes (for example, around 94.5″ x 43.31″ in some product tiles) and describe a catalog approach: multiple textures, multiple patterns, and a manufacturer-direct vibe.

Who it’s best for: you want the best eva foam for boats in a custom-sized sheet and you’re comfortable evaluating supplier specs and managing DIY fit.

Watch-outs: with manufacturer-direct options, compare adhesive details and verify how the backing is described. Your “win” is value and customization, but you should treat it like a spec-checking exercise.

Focean Boat Flooring EVA Foam

Focean is a “style-forward” option when you want something beyond standard faux teak, including bold patterns like camo. What makes it easier to compare objectively is that product pages sometimes publish measurable details such as hardness (for example, a listing that states hardness 55 (±1P)) alongside durability claims like resistance to fading and tearing.

This is a good fit if you want the visual impact but still want baseline marine behavior: closed-cell structure, non-slip function, and cleanability. Just remember that high-contrast patterns can hide scuffs well, but they can also make uneven wear more noticeable depending on the design.

Who it’s best for: you want bold patterns (including camo styles) and you still want the “marine EVA” basics like non-slip and easy cleaning.

Watch-outs: pattern-heavy surfaces can show wear differently over time. If you’re picky about uniform aging, choose patterns and colors that disguise scuffs.

Hzchione Faux Teak Eva Foam Boat Flooring

Hzchione offers faux-teak EVA foam sheets in multiple color combinations and publishes some large-format options (for example, listings that show 94.5″ x 56.3″ in multiple colorways).

Hzchione’s catalog includes language around waterproofing, shock absorption, and anti-slip traction, and some listings note 6mm total thickness for certain pads.

Who it’s best for: you want that faux teak visual in big sheets and you’re installing on relatively simple areas where large formats reduce seams.

Watch-outs: when a product is positioned with many variants, make sure you’re reading the exact listing’s size and thickness, not assuming every colorway matches.

Side-by-Side Comparison: Which EVA Foam Boat Flooring You Should Choose

The following is a comparison table of the best Eva foam boat flooring.

| Brand | Best for | Main watch-outs |

|---|---|---|

| SeaDek | Premium look and a “factory-fit” finish, especially when seam count matters | Adhesion is prep-dependent; contaminated surfaces and weak edge pressure can still cause edge lift |

| DEKit | Custom aesthetics with the widest thickness range for comfort vs low-profile installs | Performance depends on install conditions; PSA bond is sensitive to surface condition, temperature, and prep steps |

| MarineMat | Ultra-comfort underfoot for long days aboard; refined textures for barefoot cruising | Typically premium pricing; less DIY-sheet oriented, so it may be more than you need for small “test” zones |

| VEVOR | Best value DIY faux-teak look for flat or simple zones (platforms, hatches, cooler tops) | Results depend heavily on templating, clean substrate, rolling pressure, and edge attention |

| KT GuoMei | Custom-sized sheets and pattern variety when you’re comfortable DIY cutting and spec-checking | Verify backing/adhesive description per SKU; avoid assuming thickness and backing are identical across variants |

| Focean | Style-forward patterns (including camo) while keeping core marine EVA behavior | Pattern-heavy decks can show wear unevenly; confirm exact listing details before ordering |

| Hzchione | Large-format faux teak sheets to reduce seams on simpler layouts | Larger panels require careful alignment and rolling; don’t assume all variants share identical thickness or backing |

Read More: 10 Pontoon Boat Layout Ideas for 2026: Smart, Space-Saving Designs

How to Install EVA Foam Boat Flooring: DIY vs Professional Fit

If you want your best EVA foam boat flooring install to stay down, look clean, and survive heat cycles, your install process is the product. That’s not marketing. It’s PSA reality.

DIY Installation: The “Do It Right Once” Process

DIY is completely workable if your deck geometry is simple and you’re willing to slow down. Here’s the process that consistently produces good outcomes:

1) Clean beyond “looks clean.” Your deck should be free of wax, sunscreen film, oil haze, and old adhesive residue. If you’re bonding to fiberglass gelcoat, assume it has contamination unless you’ve recently stripped it. If you’re bonding to painted surfaces, confirm the paint is fully cured and not chalking.

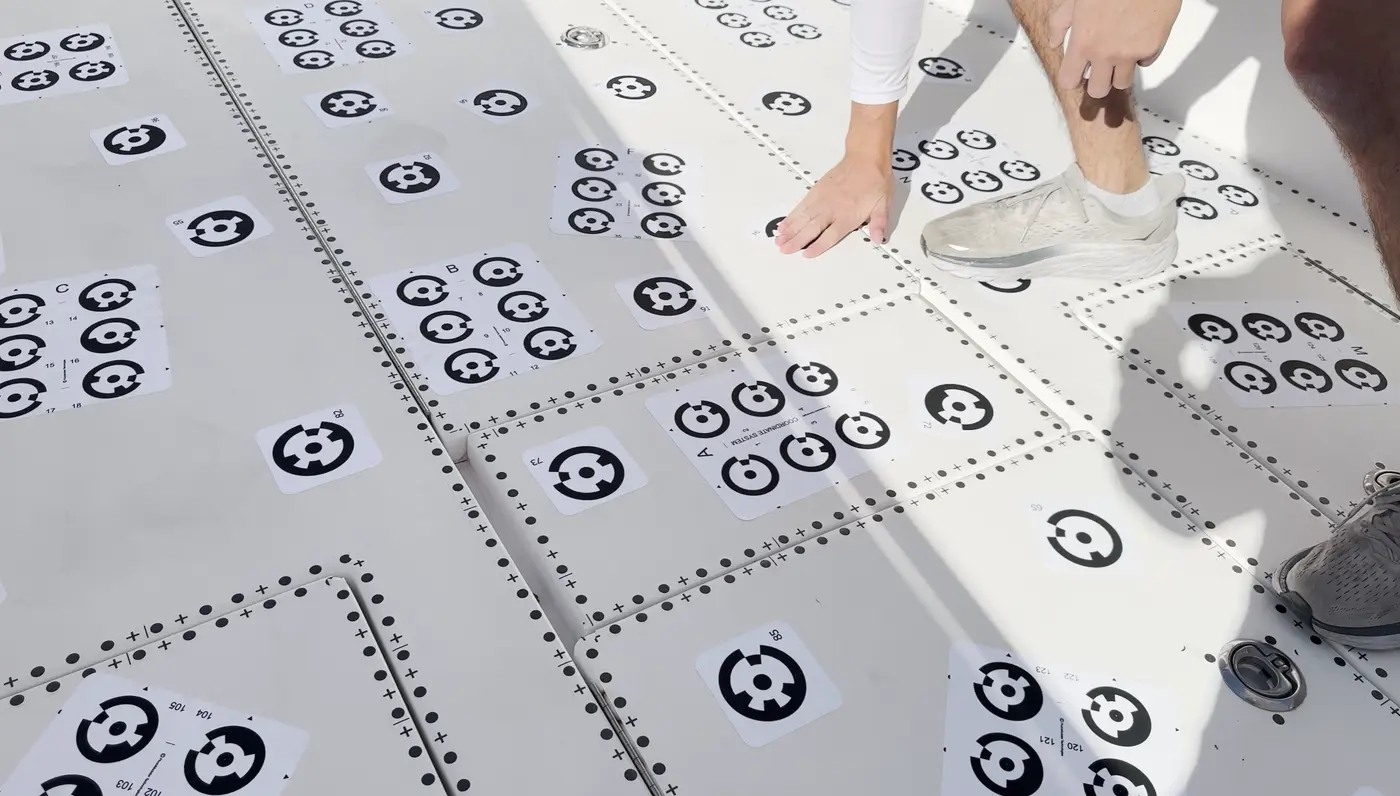

2) Make templates you can trust. Use craft paper, builder’s paper, or template film. Tape it down, trace carefully, label orientation, and mark hardware cutouts. If you’re using sheet material, template work is what makes the best eva boat flooring look like a kit.

3) Dry-fit everything. Place pieces with the backing still on. Check hatch clearance and step edges. Make sure your seams look intentional, not accidental.

4) Control temperature and humidity. PSA behaves differently when it’s cold. If the foam is stiff, it won’t conform as well, and you’ll fight edge bonding. Aim for stable conditions so the adhesive can wet out properly.

5) Peel and lay progressively. Don’t rip the whole backing off and slap it down. Peel in sections, lay from one edge, and use steady pressure.

6) Roll it like you mean it. A hand roller helps apply uniform pressure across the foam. Pressure is what makes PSA “grab.” Skipping this is how you get edges lifting later.

7) Treat edges like the mission. Edges are where water, heat, and shoes attack first. Spend time pressing, rolling, and verifying every edge segment. If your boat lives uncovered, edges deserve extra attention.

Professional Fit: When It’s Worth Paying For

Professional installs shine when your deck has complex contours, lots of cutouts, or you want a near-seamless look. Custom providers often use precise measurement workflows and CNC cutting, which reduces the “human error tax” in tight corners and around hardware. DEKit explicitly describes CNC precision cutting as part of its approach, and that’s a real functional advantage on complex boats.

Professionally fit systems also tend to minimize seams. That’s not just aesthetics. Fewer seams means fewer edge lines where dirt collects and fewer places for a corner to start lifting.

| Approach | Typical outcome | Best for | Biggest risk |

|---|---|---|---|

| DIY sheets (brushed or faux teak) | Great value, good comfort, visible seams | Flat platforms, hatches, steps, small cockpits | Edge lift from poor prep or weak rolling pressure |

| DIY “template-first” sheet install | Near kit-like look if you’re patient | Owners who enjoy detailed projects | Cutting errors compound fast; one bad cut ruins symmetry |

| Professional custom kit | Cleanest fit, fewer seams, best resale impression | Complex decks with lots of hardware cutouts | Higher cost; scheduling and lead time |

| Hybrid (pro template, DIY install) | Strong fit with owner-controlled install | Boat owners who want accuracy but like DIY | Miscommunication on templates and orientation |

Supporting source context for professional workflow language and material systems: DEKit CNC cutting description and DEKit material/PSA positioning.

Maintenance & Longevity of EVA Foam Flooring

Good EVA foam flooring is low maintenance, but it’s not “no maintenance.” If you treat it like carpet, it will punish you. If you treat it like a performance surface, it stays good-looking longer and continues to feel like Best EVA Foam Boat Flooring instead of a faded sticker.

Daily and Weekly Cleaning That Doesn’t Damage the Surface

Rinse first, then scrub. If you scrub dry dirt into foam, you’re basically sanding it. A quick rinse removes grit that causes premature surface wear.

Use mild soap and a soft brush. You want the foam to stay resilient. Harsh solvents can dry out the surface or cause discoloration, especially on lighter colorways.

Don’t chase “white-glove perfection” with aggressive chemicals. Sunscreen, blood bait residue, and beverage stains happen. The goal is clean and safe, not sterile.

Heat, Sun, and “Light Amplification” Reality

Dark colors get hotter. Faux teak lines can concentrate heat visually. And reflective surfaces (like certain windshields, polished rails, or glossy consoles) can create hot spots. Some flooring brands address this in FAQs and warranty language, which is worth reading before you blame the foam for a heat issue. DEKit’s FAQ and warranty notes include important coverage details and limitations, including factors outside the material itself.

Edge Care: The Small Habit That Extends Life

If you only do one thing for longevity, do this: inspect and press edges every so often, especially after big temperature swings. If an edge starts lifting, dirt and water will work into the gap and make it worse. Catching it early is the difference between a minor annoyance and replacing a whole piece.

How Long Does EVA Foam Flooring Really Last?

Real-world life depends on exposure (covered vs. uncovered), traffic, cleaning habits, and install quality. Brands sometimes frame longevity through warranty language (for example, DEKit positions a 3-year material warranty), while value-sheet sellers typically focus more on spec claims than long-term support.

In practical terms: if you install carefully on a properly prepared surface and you keep it reasonably clean, EVA foam flooring can stay presentable for years. If you slap it onto a waxed deck in cold weather and never roll the edges, it can fail fast. The material is only half the story.

Conclusion

The best EVA foam boat flooring choice is the one that matches your deck complexity and your tolerance for DIY precision. If you want the cleanest fit and a premium feel, SeaDek and DEKit are the obvious benchmarks, with DEKit standing out for thick comfort options and SeaDek standing out for broad customization and sheet availability.

If you want strong value, alternatives like VEVOR and other sheet-style suppliers can absolutely be the best eva foam for boats in your price range, as long as you treat installation prep and edge bonding like the main event, not an afterthought.

Frequently Asked Questions

1. Is EVA foam good for boat flooring?

Yes. EVA foam is widely used as marine decking because closed-cell EVA resists water absorption, stays lightweight, and provides comfortable traction underfoot. The key is choosing marine-grade, closed-cell material and installing it on a properly prepared surface so the PSA bond stays strong.

2. How long does EVA foam boat flooring last?

Longevity varies by exposure, traffic, and install quality. Premium systems often communicate expectations through warranty terms (for example, DEKit describes a 3-year workmanship and material warranty with important limitations), while value sheets may publish hardness and thickness specs but offer less long-term support. If you keep edges sealed and clean regularly, your flooring typically stays presentable much longer than if you ignore grit and let edges lift.

3. What is the best flooring to put in a boat?

It depends on how you use the boat. EVA foam is often the best balance of comfort, non-skid traction, and easy cleaning for cockpits and swim platforms. Woven vinyl can be great for drainage-heavy use. Real teak looks amazing but brings cost and maintenance. If your main goal is barefoot comfort plus safe traction, the best EVA foam boat flooring options are usually the most satisfying upgrade for the money.

4. What is the best foam for boats?

For decking surfaces, you generally want marine-grade, closed-cell EVA (often described as EVA or PE/EVA) that’s designed for UV exposure and paired with a quality PSA backing. Closed-cell structure is the big differentiator because it helps prevent water uptake and supports quick drying.

5. How does SeaDek compare with DEKit in quality and customization?

Both sit at the premium end of the best EVA foam boat flooring. SeaDek emphasizes broad customization and peel-and-stick usability across custom kits and sheet material, and it publishes practical sheet specs (like 40″ x 80″ brushed sheets at 5mm). DEKit highlights cross-linked PE/EVA foam, UV protectants, 3M PSA language, a wide thickness menu (including 13mm and 25mm options), and a 3-year material warranty position with specific limitations. If you want thicker comfort builds, DEKit’s thickness range is a standout; if you want a broadly recognized premium standard with widely available sheet options, SeaDek is hard to beat.

References

SeaDek. (n.d.). Custom brushed full sheet. SeaDek. https://www.seadek.com/product/custom-brushed-full-sheet/

DEKit. (n.d.). DEKit boat flooring. DEKit. https://dekit.com/pages/dekit-boat-flooring

DEKit. (n.d.). Foam boat decking designs & color options. DEKit. https://dekit.com/pages/dekit-designs-colors

VEVOR. (n.d.). 94.5″ x 47.2″ EVA faux teak boat decking foam sheet (hardness 60). VEVOR. https://www.vevor.com/eva-foam-decking-sheet-c_10541/94-5×47-2-eva-teak-decking-foam-boat-sheet-dark-grey-teak-like-premium-material-p_010339397563

KT GuoMei. (n.d.). Boat flooring sheets. KT GuoMei. https://ktguomei.com/collections/boat-flooring-sheets

KT GuoMei. (n.d.). Best DIY EVA foam boat flooring (manufacturer site). KT GuoMei. https://ktguomei.com/

Focean. (n.d.). Anti-UV diamond camo EVA foam boat flooring. Focean Shop. https://foceanshop.com/products/focean-anti-uv-diamond-camo-eva-foam-boat-flooring

Hzchione. (n.d.). Faux teak EVA foam boat flooring U-groove large size. Hzchione. https://www.hzchione.com/products/hzchione-faux-teak-eva-foam-boat-flooring-u-groove-large-size

BoatFloorings.com. (2025, September 25). Technical advantages of EVA foam in marine flooring. BoatFloorings.com. https://boatfloorings.com/blogs/our-journal/technical-advantages-eva-foam-marine-flooring